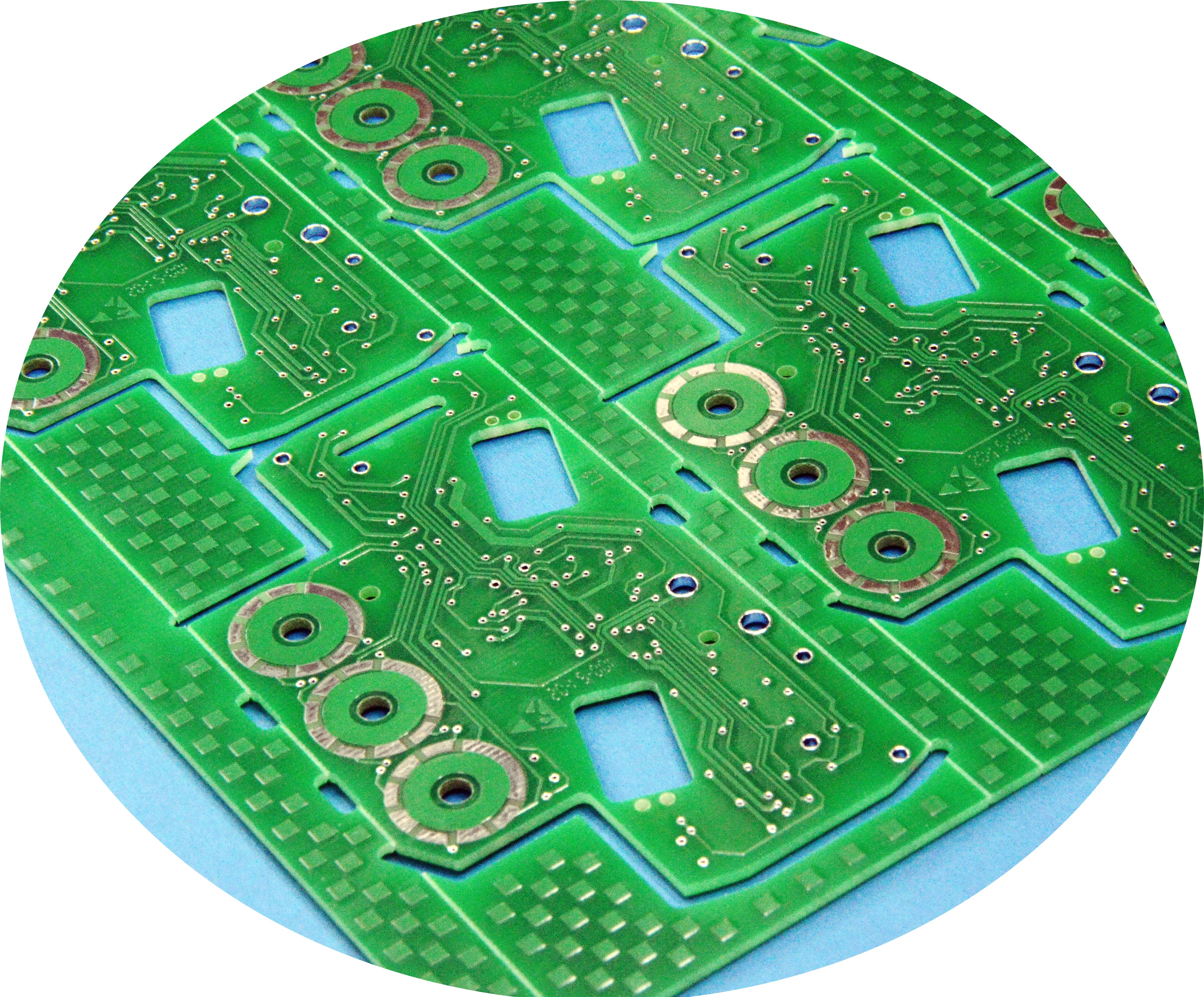

Finishing Services

A huge choice of finishing services. Scroll down for more information...

A surface finish can be either organic or metallic in nature. Comparing both types and all available options can quickly demonstrate the relative benefits or drawbacks. Typically, the decisive factors when it comes to selecting the most suitable finish is the end application, the assembly process and the design of the PCB itself. Below you can find a brief summary of the most common finishes, however for further or more detailed information, please Contact Us and we will be more than happy to answer any of your questions.

HASL – Tin/Lead hot air solder level

Typical thickness 1 – 40um. Shelf life:12 months

HASL is the predominant surface finish used in the industry. The process consists of immersing circuit boards in a molten pot of a tin/lead alloy and then removing the excess solder by using ‘air knives’, which blow hot air across the surface of the board. One of the unintended benefits of the HASL process is that it will expose the PCB to temperatures up to 265°C which will identify any potential delamination issues.