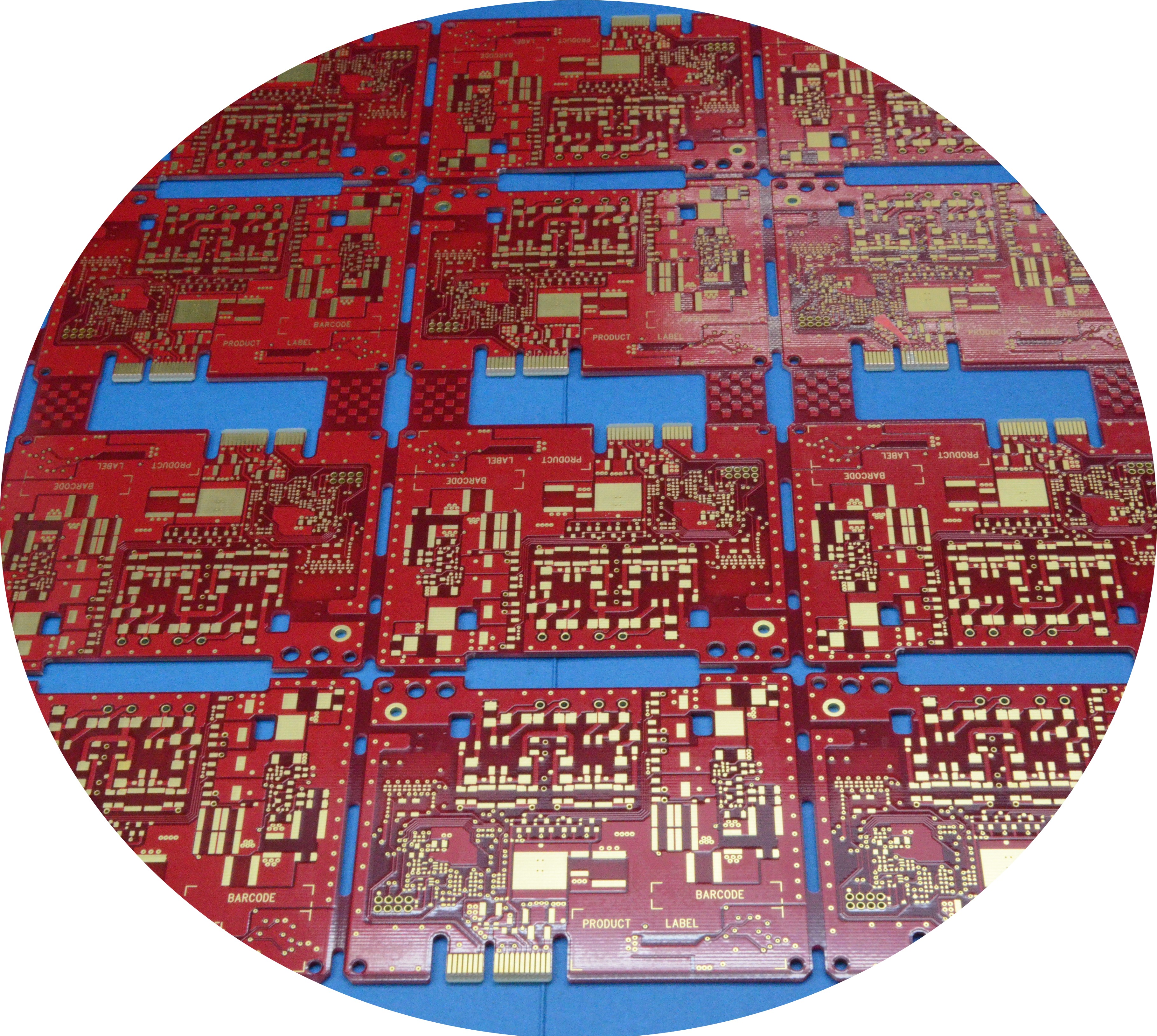

Finishing Services

A huge choice of finishing services. Scroll down for more information...

A surface finish can be either organic or metallic in nature. Comparing both types and all available options can quickly demonstrate the relative benefits or drawbacks. Typically, the decisive factors when it comes to selecting the most suitable finish is the end application, the assembly process and the design of the PCB itself. Below you can find a brief summary of the most common finishes, however for further or more detailed information, please Contact Us and we will be more than happy to answer any of your questions.

Ni/Au – Electrodeposit Nickel and Gold Plating

Typical thickness (can vary depending on customer requirements) Flash Au : Ni – 3um minimum; Au – 0.025 to 0.05um Hard Au : Ni – 3um minimum, Au 0.075um to 1.75um

Flash Au plating is commonly used for aluminium wire bonding or soldering application whereas Hard Au finish is used in edge conncector or contact switch. Selective Ni/Au plating can allow Ni/Ai plating on specific area to facilitate customer special application and requirement. The gold deposit can fullfit ASTM B488 requirement.