Finishing Services

A huge choice of finishing services. Scroll down for more information...

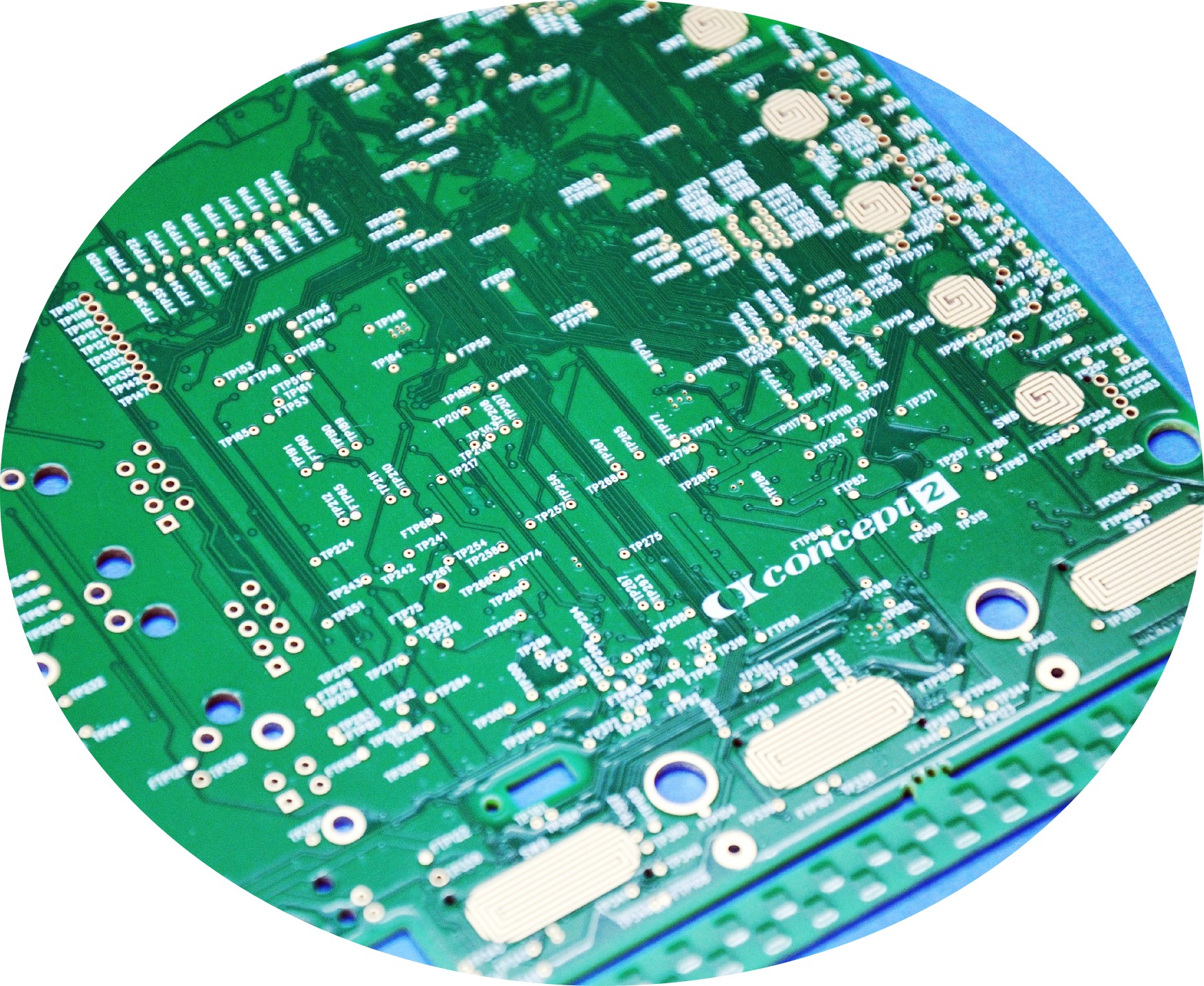

A surface finish can be either organic or metallic in nature. Comparing both types and all available options can quickly demonstrate the relative benefits or drawbacks. Typically, the decisive factors when it comes to selecting the most suitable finish is the end application, the assembly process and the design of the PCB itself. Below you can find a brief summary of the most common finishes, however for further or more detailed information, please Contact Us and we will be more than happy to answer any of your questions.

ENIG – Immersion gold / Electroless Nickel Immersion Gold

Typical thickness 3 – 6um Nickel / 0.05 – 0.075um Gold. Shelf life: 12 months

Electroless nickel immersion gold (ENIG) is a type of surface plating used for printed circuit boards. It consists of an electroless nickel plating covered with a thin layer of immersion gold, which protects the nickel from oxidation. The ENIG finish has historically been the best fine pitch (flat) surface and lead-free option world-wide. Benefits to this surface finish are a long-term experience/knowledge of the product and an excellent shelf life.